Inside GEM

Welcome to Inside GEM — your window into the projects, people, and expertise that drive GEM Industrial. Here we share updates from the field, insights into large-scale plumbing and infrastructure work, and the innovations shaping our industry. Stay connected with the latest news, case studies, and professional perspectives from the team setting the standard in industrial plumbing across Australia.

Engineering the Simple Things Properly

GEM's team designed and fabricated 20 large‑bore pipe trolleys, engineered to solve a very real on‑site challenge: moving heavy pipe safely, efficiently, and without compromising material integrity.

Milestone Moment at GEM Industrial

When the first batch of pipework officially rolled out from our GEM workshop — this was a proud step that highlights both our fabrication capability and delivery strength.

Expanding Horizons:

Mechanical Installation of a Brand New Poly Batching Unit.

At GEM Industrial, we’re best known for our expertise in HDPE fusion welding and infrastructure delivery.

Not every HDPE pipeline project gives you a straight run.

In Melbourne’s eastern suburbs, our crews are deep into a live installation where welded HDPE strings sometimes can’t be built in place.

Massive HDPE Fittings Arrive for GEM Industrial

We’re proud to announce the arrival of these massive RBT 1800 mm HDPE fittings, supplied by our trusted partner Thai-Asia P.E. Pipe Co., LTD. These fittings mark a major milestone in GEM’s capability to deliver high-volume water infrastructure at scale.

Bespoke HDPE solutions under pressure

GEM Industrial recently supported an Anaerobic Cover Replacement project with a custom approach to critical sludge return and feed lines—delivered under tight timelines and complex site conditions:

From the French Alps to Fusion Welding

Braden Wright’s Journey with GEM Industrial.

At GEM Industrial, we know that great teams aren’t built overnight — they’re forged through grit, skill, and a good dose of humour. And few people embody that spirit better than Braden Wright.

Precision Welding and Installation

At GEM Industrial, our core expertise in HDPE welding is well-established — but this recent pilot plant installation in Gippsland highlights our broader capability in multi-material process pipework fabrication.

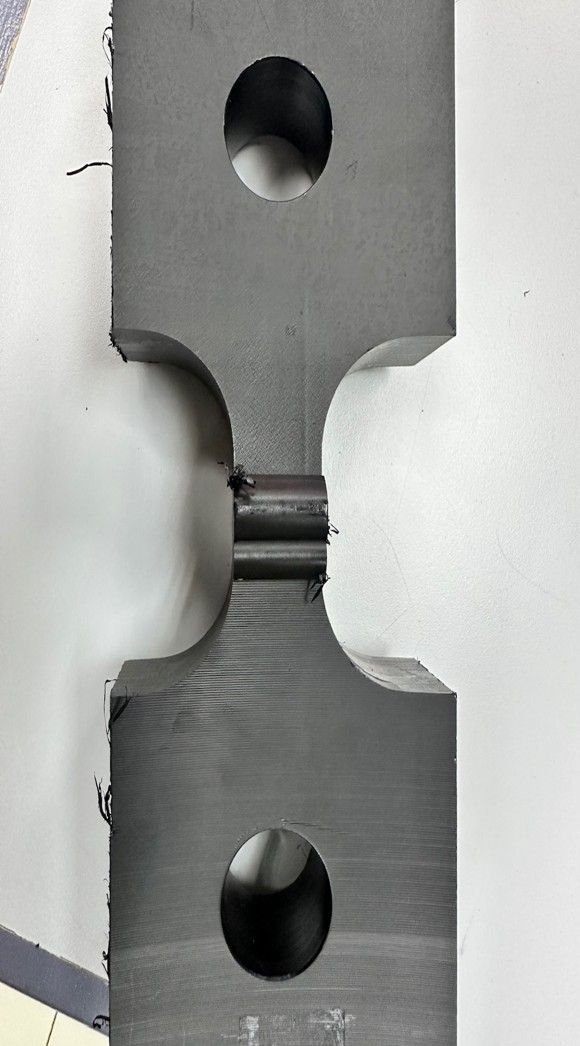

Quality isn’t just a promise — it’s a process

Our commitment to excellence in HDPE fabrication is reinforced by rigorous destructive testing of butt welds, ensuring every joint meets the highest standards of strength, durability, and safety.

Delivering quality work on the ground

Always proud to see our team delivering quality work on the ground. Here’s a recent field highlight from one of our crew — a great example of skill, pride, and teamwork in action.

HDPE Side Fusion: Precision Fabrication at Scale

Early 2024, GEM Industrial enhanced its workshop capabilities by commissioning the Omisa 160 SW-S Side Fusion Machine, tailored for HDPE sidewall welding.

What a week at hashtag#INFUSION25 in Tulsa!

Nearly 600 industry leaders, innovators, and HDPE champions came together to exchange ideas, spark collaboration, and shape the future of infrastructure

Metro Melbourne

It’s been a cracking few weeks for the team at GEM Industrial, Leongatha, supporting key works across Metro Melbourne!

Existing Potable water network

When tasked with connecting into an existing water network during site establishment, GEM Industrial faced a challenge: the nearest isolation point was many hundreds of meters from the tie-in, and draining the line would chew through precious shutdown hours.

Tradewaste Pipeline Renewal Project

From our beginnings in South Gippsland’s dairy industry, GEM Industrial has grown into a trusted partner for complex pipeline infrastructure projects across Australia.

Delivering Excellence at Bryn Estyn Water Treatment Plant

The Bryn Estyn Water Treatment Plant is the primary drinking water source for Greater Hobart, supplying approximately 60% of the region’s water across Hobart, Glenorchy, Clarence, Brighton, Derwent Valley, Kingborough, Sorell, and the Southern Midlands.

Saturator Replacement

With the existing saturator reaching the end of its service life, a full isolation procedure was developed and executed using LOTO (Lockout/Tagout) practices to ensure safe removal.

Biogas Roof Removal

This week GEM Industrial's Mechanical Team removed another digester biogas double membrane roof. Double membrane roof removal is required for internal cleaning, maintenance, repairs, refurbishment or decommissioning of the digester.

Expanding the Fusion Fleet at GEM Industrial

Since investing in our first McElroy Manufacturing fusion machine back in 2008, GEM Industrial has proudly relied on their world-class technology across countless projects. They’re the gold standard in polyethylene welding—and we’ve built a fleet around them.

Major Milestone at Beach Street

Early 2024, a large drill rig arrived on site to support water service relocations as part of the Swan River crossing works. In August, the first pilot hole was successfully drilled to a depth of approximately 50m.