Quality isn’t just a promise — it’s a process

At GEM Industrial, quality isn’t just a promise — it’s a process.

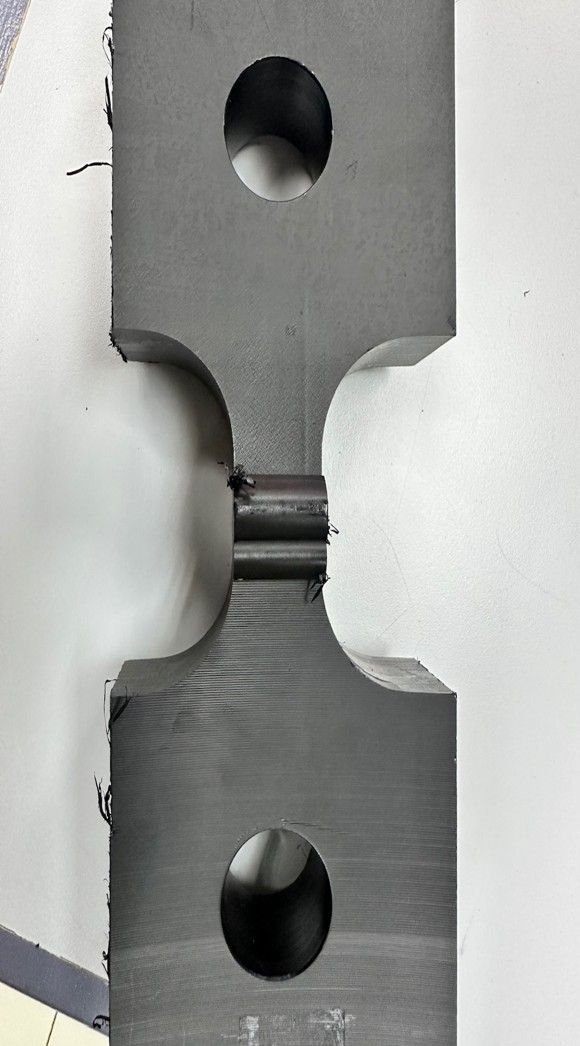

Our commitment to excellence in HDPE fabrication is reinforced by rigorous destructive testing of butt welds, ensuring every joint meets the highest standards of strength, durability, and safety.

By physically testing samples to failure, we gain critical insights into weld strength, fusion quality, and long-term performance — insights that non-destructive methods simply can't provide.

Our Process Includes:

- Tensile testing to measure joint strength under stress

- Bend testing to assess ductility and fusion consistency

- Peel testing for multilayered welds and complex assemblies

Weather it's a Qualification or Process test on Butt, Electrofusion, or Side Fusion weld, from as small as DN32 or as large as our upcoming DN1800 project, you can count on GEM Industrial to deliver HDPE welds that are tested and qualified to last.